|

Ningbo Free Trade Zone ECO International CO.,Ltd

|

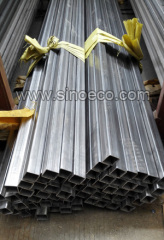

Ss 316 304 Sanitary Steel Seamless / Welded Polished / Industrial Pipes

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

SS 201 304 316 316L stainless steel seamless pipes, ss welded pipes, ss sanitary/ process seamless pipes, SS polished mirror pipe

Product Description

| Product Details | |

Product name | Stainless steel pipe |

Brand name | ECO |

Standard | ASTM A312, ASTM A554, ASTM A790, EN10216-5, EN10217-7, JIS G3468, JIS G3459 |

Material | 304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

Technic | Hot rolled, cold rolled , cold drawn |

Certificate | ISO |

Packing | In bundles with waterproof material, in wooden cases |

Shipment | By sea, by air, by express |

Dimensions:

| DN | INCH | MM | SCH5s | SCH10s | SCH40s | STD | SCH40 | SCH80s | XS | SCH80 | SCH160 | XXS |

| 6 | 1/8 | 10.29 | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | |||

| 8 | 1/4 | 13.72 | 1.65 | 1.73 | 1.73 | 1.73 | 3.02 | 3.02 | 3.02 | |||

| 10 | 3/8 | 17.14 | 1.65 | 2.31 | 2.31 | 2.31 | 3.2 | 3.2 | 3.2 | |||

| 15 | 1/2 | 21.34 | 1.65 | 2.11 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 26.67 | 1.65 | 2.11 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 33.4 | 1.65 | 2.77 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 |

| 32 | 11/4 | 42.16 | 1.65 | 2.77 | 3.56 | 3.56 | 3.56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.7 |

| 40 | 11/2 | 48.26 | 1.65 | 2.77 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.2 |

| 50 | 2 | 60.32 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.1 |

| 65 | 21/2 | 73.02 | 2.11 | 3.05 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.52 | 14 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.12 | 15.2 |

| 90 | 31/2 | 101.6 | 2.11 | 3.05 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | ||

| 100 | 4 | 114.3 | 2.11 | 3.05 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 13.49 | 17.1 |

| 125 | 5 | 141.3 | 2.77 | 3.4 | 6.55 | 6.55 | 6.55 | 9.53 | 9.53 | 9.53 | 15.88 | 19.1 |

| 150 | 6 | 168.3 | 2.77 | 3.4 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 18.26 | 21.9 |

| 200 | 8 | 219.1 | 2.77 | 3.4 | 8.18 | 8.18 | 8.18 | 12.7 | 12.7 | 12.7 | 23.01 | 22.2 |

| 250 | 10 | 273.1 | 3.4 | 3.76 | 9.27 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 28.58 | 25.4 |

| 300 | 12 | 323.9 | 3.96 | 4.57 | 9.52 | 9.52 | 10.31 | 12.7 | 12.7 | 17.48 | 33.32 | 25.4 |

| 350 | 14 | 355.6 | 3.96 | 4.78 | *9.52 | 9.52 | 11.13 | 12.7 | 12.7 | 19.05 | 35.71 | |

| 400 | 16 | 406.4 | 4.19 | 4.78 | *9.52 | 9.52 | 12.7 | 12.7 | 12.7 | 21.44 | 40.49 | |

| 450 | 18 | 457.2 | 4.19 | 4.78 | *9.52 | 9.52 | 14.27 | 12.7 | 12.7 | 23.82 | 45.24 | |

| 500 | 20 | 508 | 4.78 | 5.54 | *9.52 | 9.52 | 15.09 | 12.7 | 12.7 | 26.19 | 50.01 | |

| 550 | 22 | 558.8 | 4.78 | 5.54 | *9.52 | 9.52 | 12.7 | 12.7 | 28.58 | 53.98 | ||

| 600 | 24 | 609.6 | 5.54 | 6.35 | *9.52 | 9.52 | 17.48 | 12.7 | 12.7 | 30.96 | 59.54 | |

| 650 | 26 | 660.4 | *7.92 | *9.52 | 9.52 | 12.7 | 12.7 | |||||

| 700 | 28 | 711.2 | *7.92 | *9.52 | 9.52 | 12.7 | 12.7 | |||||

| 750 | 30 | 762 | 6.35 | *7.92 | *9.52 | 9.52 | 12.7 | 12.7 | ||||

| 800 | 32 | 812 | *7.92 | *9.52 | 9.52 | 17.48 | 12.7 | 12.7 | ||||

| 850 | 34 | 863.6 | *7.92 | *9.52 | 9.52 | 17.48 | 12.7 | 12.7 | ||||

| 900 | 36 | 914.4 | *7.92 | *9.52 | 9.52 | 19.05 | 12.7 | 12.7 |

Surface:

| Surface Finish | Definition | Application | ||||||

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. | ||||||

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. | ||||||

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. | ||||||

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. | ||||||

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. | ||||||

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. | ||||||

Related Search

Seamless Steel Pipes

Api Seamless Steel Pipes

Shipbuilding Seamless Steel Pipes

Seamless Mechanical Steel Pipes

Precision Seamless Steel Pipes

Alloy Seamless Steel Pipes

More>>